What are the components of automotive wiring harnesses?

The basic idea of automotive wiring harness design is to determine the circuit loop based on the requirements of the electrical equipment and calculate the voltage and current of each loop, especially for high-power equipment. Select the matching connectors according to the electrical equipment, determine the cross-sectional area of the wiring harness based on the current, and then design the wiring harness layout.

Overview of Wiring Harness Design

The basic process of wire harness development and design is as follows:

(1) According to the function list required by the main engine manufacturer, list all the functional components connected to the wiring harness, confirm the component functions with the corresponding electrical engineer, obtain ICD information, and determine the electrical principle layout diagram. Verify the principles of each ECU system and integrate all functional components into a completed wiring harness schematic diagram. Generally, the power supply system and the grounding part can be combined by riveting points. At the same time, check the current size of each functional system (including overcurrent or locked-rotor current, etc.) to ensure that it can meet the working requirements of electrical systems such as motors, switches, fuses, and blowers.

(2) Design the initial 3D distribution diagram. According to the processing and assembly sequence of the general wire harness process, complete the routing distribution of the wire harness using CATIA or UG software. During this process, the installation position of the fuse box needs to be basically defined, and the initial 3D distribution drawing usually reserves a certain margin.

(3) Convert 2D drawings. The 2D drawings should refer to industry standards, such as the relevant requirements in the QC29106 standard.

(4) Based on the initial 2D drawings, make manual wiring harness samples and test assemble them in the vehicle.

(5) Based on the actual trial installation results and trial operation results, the 3D wiring engineer of the wire harness is optimizing and adjusting the direction or length of the wires, taking into account dynamic conditions.

(6) Wiring harnesses are used in conjunction with the installation and connection of the vehicle's electrical functional components. Due to the installation requirements of various electrical systems or the entire vehicle, wiring harnesses generally need to be constantly adjusted and optimized in accordance with each system. That is, the entire development process is also a process of continuous optimization and update of the design.

Wire Harness Design Method

1. Principle design of wiring harnesses

(1) Request the vehicle manufacturer for the electrical functions of the entire vehicle, current requirements and other special requirements. And confirm all information such as the installation location of the electrical components, the assembly method of the electrical components and wiring harnesses, and the working environment.

(2) Based on the functions and methods that the customer needs to achieve, create electrical schematic diagrams and circuit layout diagrams.

(3) Allocate energy to each electrical component system, including the distribution of power lines and grounding wires.

(4) Determination of the wire diameter. First, the current that the wire needs to pass through is obtained from the actual power of the electrical component. Long-term working components use wires with 60% of the actual current-carrying capacity (such as heating systems, entertainment systems, and safety systems); For short-term working components, wires with an actual current-carrying capacity of 60% to 100% should be used. For example, seat adjustment motors, window lift motors, Angle adjusters, etc.

2. 3D wiring harness design

The three-dimensional layout of the wiring harness is generally carried out under the premise of meeting the installation requirements of the vehicle's electrical system, in combination with the layout of the body sheet metal and the design of openings and grooves, to achieve an overall layout. In particular, the segmented design of the wiring harness and the positioning of the main trunk should take into account the overall layout.

2.1 Requirements for Three-dimensional Wiring of Automotive Wiring Harnesses

The three-dimensional wiring of automotive wiring harnesses from existence to non-existence is a complex project, mainly referring to the following points:

(1) Ensure that all electrical functional areas are easy to assemble, and the final assembly section should be as simple as possible to facilitate installation. If there are parts that are not suitable for direct installation, it is advisable to consider installing the accessories inside, installing them separately and then assembling them together (this will increase the cost). The tail lines for door panels, interiors, etc. can be assembled separately. Try to ensure that the assembly process can be achieved through traditional technological procedures and tooling.

(2) Besides assembly, maintenance and repair should also be emphasized. It is also necessary to be easy to disassemble, which is commonly referred to as DFD (design for disassembly). During maintenance, only a section of the wire needs to be removed, which is much easier to operate than removing the entire wire harness. At the same time, it saves costs and reduces potential risks.

2.2 Other details of the wiring harness layout

In addition to the convenience of assembly and disassembly mentioned above, the wiring harness layout also needs to take into account the following details:

(1) Reserve sufficient margin (even under the lower limit of tolerance), especially for wiring harnesses between two or more components with relative motion. The length required at the limit position must be taken into consideration.

(2) The wiring harness should not remain taut all the time; otherwise, it will continuously exert internal stress on the copper sheets of the wires, accelerating their aging process.

(3) Wire harnesses generally need to be fixed at intervals with clips or slots and should not have a long free state.

Part selection

1. Wire selection of Cable Assemblies

When choosing wires for a wiring harness, the key considerations should be the functions and environments that the wiring harness needs to achieve. For instance, in the case of engine wiring harnesses, the cabin temperature is very high and there are many corrosive substances. Therefore, materials that are resistant to high temperatures and oil corrosion should be selected, such as Teflon or cross-linked PE.

The trunk or the car door moves frequently. Therefore, it is necessary to choose a wiring harness with higher elasticity, such as TPE or rubber types. For some weak signal types, composite shielded wires are generally used, such as detonation sensor wiring harnesses, etc. The requirements for the cab are relatively low. It is advisable to consider using PVC-type wiring harnesses, which can save costs and be beneficial for lightweighting.

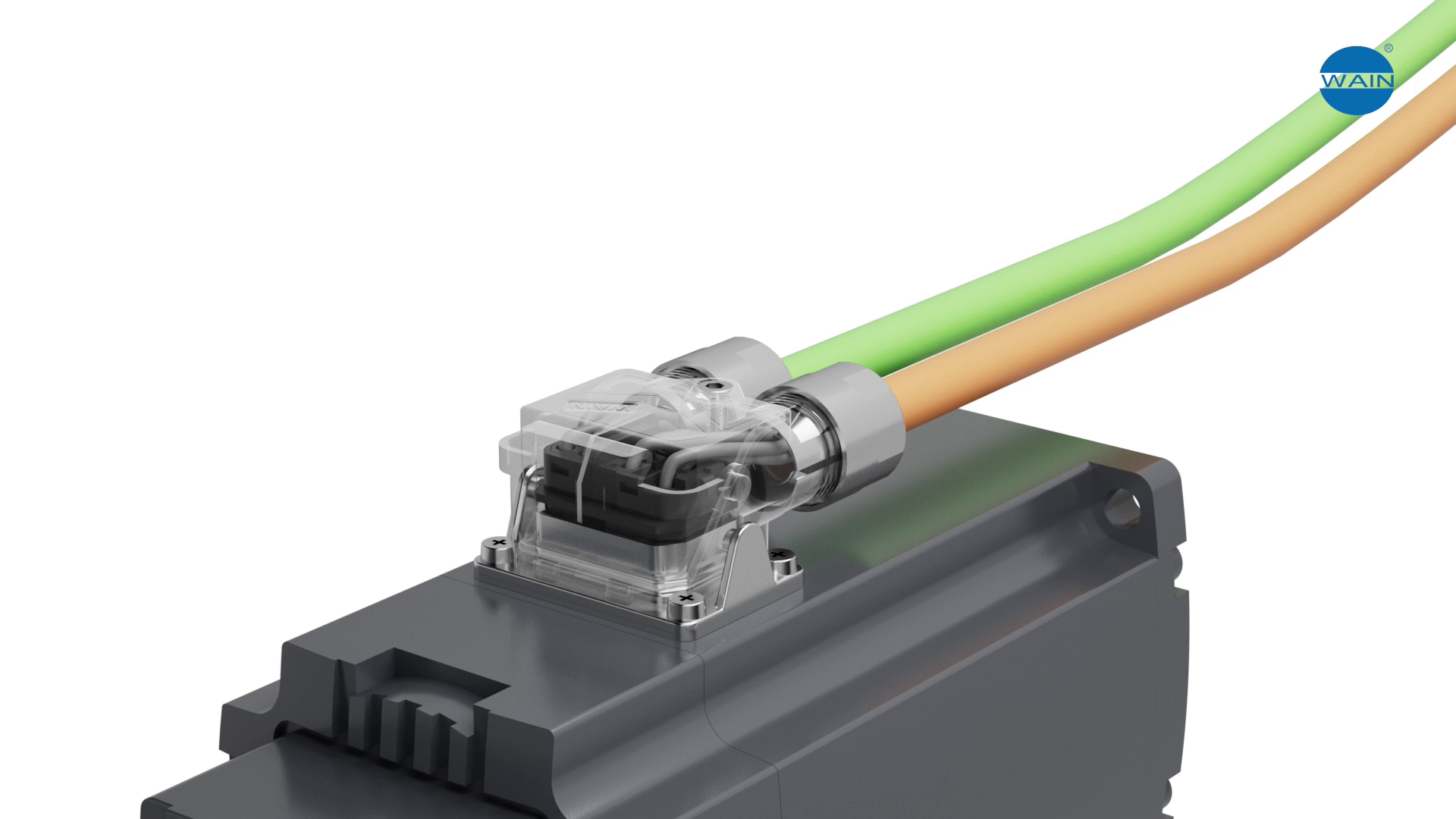

2. Connector

Connectors are the most crucial components of wiring harnesses, directly determining whether the wiring harness can achieve the most core connection function and playing a decisive role in the stability of electrical systems.

2.1 Selection Requirements for Connectors

Firstly, it is the coordination with the electrical components. The mechanical insertion holding force should meet the usage requirements, and a design with a secondary lock should be preferred. Contact resistance should be as low as possible. The insulation resistance and overcurrent comply with the working current requirements of the conductor. For wire harnesses located in wet areas, waterproof sheaths should be selected and appropriate sealing rings or blind plugs should be matched to meet the requirements of different waterproof levels in different areas.

2.2 Performance of Raw Materials for Connectors

① Sheath material (plastic part) :

The commonly used materials for current connectors mainly include PA66, PBT, ABS, etc. Generally, some additives need to be added to enhance the performance of the materials, such as adding glass fiber to increase strength and adding plasticizers to increase softness.

② Terminal material (copper part) :

The commonly used materials for terminals are brass, bronze and copper alloys. Brass has strong wear resistance, bronze has good castability, is wear-resistant and has stable chemical properties, and copper alloys have excellent electrical conductivity, thermal conductivity, ductility and corrosion resistance. In addition, considering salt spray and aging, terminals usually need to be coated with different layers, such as tin plating and gold plating.

2.3 Connector Classification

According to the connection form of connectors, they can be classified as: wire-to-wire and wire-to-board.

① Wire-to-Wire

Wire-to-wire connection includes the form of wire-to-cable or cable-to-cable, and its defining feature is that two single individual wires or the corresponding conductors in two cables are permanently connected to each other.

② Wire-to-Board

Wire-to-board connection mainly involves one end of the connector being connected to a wire or cable, while the terminal on the other end of the connector is fixed and welded to the substrate.

Wire harness covering design

Automobile wiring harnesses are exposed to various external factors for a long time inside the vehicle, such as oil stains, dust, friction, and rusting due to water imitation. If there is no protective material on the wiring harness, the exposed wires are prone to damage, such as broken wires and short circuits, which may lead to functional failure. The commonly used materials for bandaging are as follows:

1. Corrugated pipe

Corrugated tubes are the most important wiring harness protection materials used in automotive wiring harnesses and are generally divided into single-sided opening and sealed type sleeves.

The materials used are PE, PA6/66, PP, etc. The temperature resistance is generally in three grades: -40℃ to 85℃, -40℃ to 125℃, and -40℃ to 150℃. It has good wear resistance and excellent high-temperature resistance, flame retardancy and heat resistance in high-temperature zones. PA material is better in terms of flame retardancy and wear resistance, while PP material has an advantage in terms of resistance to bending fatigue.

2. Adhesive Tape

Tape is the most widely used covering method in wiring harnesses, mainly divided into three types: PVC tape, flannel tape and fabric-based tape. PVC tape has relatively good insulation performance, with a general temperature resistance of 80℃. Even after improvement, it is usually only 105 ℃. It has poor noise reduction performance and the wiring harness is relatively hard after coating. Currently, its VOC effect is generally poor. The base materials of flannel tape and cloth tape are generally PET. Flannel tape can withstand temperatures around 105 ℃, has good noise reduction performance, and the wiring harness is relatively soft after coating. Cloth tape has the best wear resistance, generally reaching a wear resistance grade of D or E, and its temperature resistance can also reach 150 ℃. However, it is relatively expensive and is usually used in places with holes or relative movement.

3. Braided mesh pipe

The material of the braided pipe is generally made of PA66 monofilament or PET monofilament. It is usually available in open and closed types. Its feature is extremely high wear resistance, but its noise reduction performance and cost are also relatively high. It is generally used in parts that are in long-term relative motion.

Automotive wiring harnesses are known as the vascular system of automobiles. With the rapid development of automobiles and the continuous improvement of user experience, the requirements for automotive wiring harnesses are also constantly increasing. It is even more necessary for automotive wiring harness professionals to continuously research and develop new solutions in order to meet the ever-changing demands.