Equivalent Series Resistance (ESR) is a critical parameter for evaluating the performance of a crystal oscillator, directly reflecting the degree of energy loss during its resonant state. Whether for kHz-range tuning fork crystal units or MHz-range AT-cut crystal units, the ESR value is influenced by a combination of factors. A deep understanding of the relationship between ESR, package size, and operating frequency is essential for optimizing circuit design and component selection.

ESR Characteristics of kHz Crystal Units

In the kHz frequency range, crystal oscillators typically utilize a tuning fork crystal element. Due to their specific vibration mode, kHz crystals generally exhibit relatively high ESR values. Our product data shows a clear correlation between package size and ESR for kHz crystal units:

1.6×1.0mm package : Maximum ESR of 90 kΩ

2.0×1.5mm package : Maximum ESR of 70 kΩ

3.2×1.5mm package : Maximum ESR of 70 kΩ

6.9×1.4mm package : Maximum ESR of 65 kΩ

8.0×3.8mm package : Maximum ESR of 50 kΩ

10.4×4.06mm package : Maximum ESR of 50 kΩ

These ESR characteristics give kHz crystal oscillators distinct advantages in low-power applications, making them particularly suitable for IoT devices and portable electronics requiring long battery life.

ESR Analysis of MHz Crystal Units

MHz crystal oscillators employ an AT-cut thickness-shear vibration mode, and their ESR characteristics follow more complex patterns. Based on our technical analysis, the ESR of an MHz crystal unit is influenced by both its package size and its operating frequency.

For a given package size, ESR typically decreases as the frequency increases. This is primarily because higher-frequency crystals use thinner crystal blanks, resulting in lower vibrating mass and relatively reduced energy loss. However, the specific ESR value must be determined by considering both the specific frequency point and the package size .

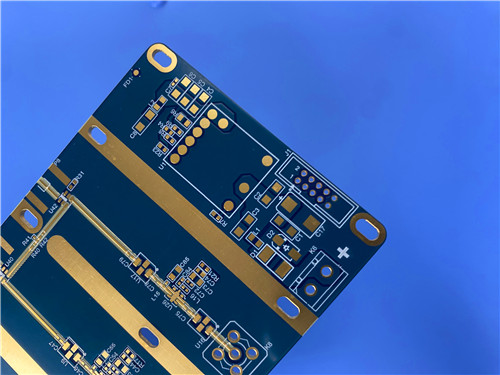

Our product line covers various package sizes from 1.6×1.2mm to 7.0×5.0mm, with each package optimized for specific frequency ranges and ESR requirements.

In-Depth Technical Principle Analysis

Mechanism of kHz Crystals :

Tuning fork crystals have a relatively large vibration amplitude. The package size directly affects the vibration space of the tuning fork arms and the air damping effect. A larger package provides a more sufficient vibration environment, reducing mechanical constraints, which helps lower the ESR.

Mechanism of MHz Crystals :

The ESR characteristics of the AT-cut thickness-shear mode are more complex. Beyond the influence of package size, the operating frequency becomes a key factor determining the ESR value. Due to their thinner crystal blanks and optimized electrode design, high-frequency crystals generally achieve lower ESR values. This inverse relationship between frequency and ESR is a key characteristic of MHz crystal oscillators .

Professional Application Selection Guide

Selection Strategy for kHz Crystals :

Ultra-Low-Power Devices (e.g., smartwatches, IoT sensors): Prioritize 1.6×1.0mm or 2.0×1.5mm packages .

Industrial Control and Automotive Electronics: Recommend 3.2×1.5mm and larger package sizes .

High-Precision Timing Modules : Choose larger package sizes like 8.0×3.8mm for better stability.

Selection Strategy for MHz Crystals :

It is necessary to understand the ESR characteristics at the specific frequency point in detail.

Comprehensively consider the relationship between package size and operating frequency.

Select the appropriate ESR range based on the power consumption and stability requirements of the application scenario.

Technology Development Trends

As electronic products evolve toward multi-functionality and miniaturization, crystal oscillator technology continues to innovate. In the kHz domain, we are developing even smaller package technologies to reduce size further while maintaining low-power characteristics. In the MHz domain, technological development focuses on supporting higher frequencies and better ESR performance within smaller dimensions.

System-in-Package (SiP) technology shows great potential in both frequency ranges. By integrating the oscillation circuit with the crystal resonator, the overall ESR characteristics can be optimized. We are committed to providing more precise frequency control solutions through continuous technological innovation.

Conclusion

The ESR characteristics of a crystal oscillator result from the combined effects of package size, operating frequency , and crystal blank design. For kHz crystals, ESR is primarily influenced by package size, whereas for MHz crystals, the complex interaction between package size and operating frequency must be considered simultaneously.

A correct understanding of ESR helps engineers make more accurate component selection decisions during project development. We recommend carefully evaluating the requirements of the specific application and selecting the most suitable crystal oscillator product based on the operating frequency and package requirements.

Contact Us

Want to know more about A-Crystal’s Technology products?

Need selection the model or technical consultation?

Feel free to contact us via the following methods!

Tel: 0086-576-89808609

Email: market@acrystals.com

Website: [www.acrystals.com](http://www.acrystals.com)

We provide comprehensive technical support to help customers choose the most suitable crystal solution based on specific application scenarios and performance requirements, ensuring optimal system performance and reliability.