Aerospace wiring harnesses Key Applications, Technical Challenges and Market Prospects

Aerospace wiring harnesses, as the "neural network" of aircraft, are deeply hidden but undertake the crucial mission of transmitting power and signals, and are an important guarantee for the normal operation of aerospace equipment.

I. Key Mission: Diverse Applications of Wiring Harnesses

In the aerospace field, wiring harnesses are responsible for the power transmission of core systems. Aircraft power distribution systems, such as urban power grids, precisely distribute electrical energy to subsystems like engines, avionics, and flight control systems through wiring harnesses, maintaining the stable operation of the electrical system. Spacecraft rely on wiring harnesses to efficiently transmit the electrical energy from solar panels and batteries to life support systems and scientific experimental equipment, meeting the requirements for long-term stays.

The wiring harness is also the "information superhighway" of the aircraft. Modern avionics rely on wiring harnesses to exchange information among sensors, controllers and actuators in real time, ensuring navigation, communication and monitoring functions. Satellites transmit Earth observation data and communication signals through wire harnesses. The cockpit of an aircraft receives instrument signals through wiring harnesses to ensure flight safety.

In addition, wiring harnesses are indispensable in special scenarios. The lighting system relies on the wiring harness to illuminate the indicator lights and the equipment inside the cabin. The thermal control system connects the heating and cooling devices through wiring harnesses to cope with extreme temperatures. Environmental sensors transmit air pressure, humidity and radiation data through wiring harnesses, providing a basis for safe flight.

II. Stringent Tests: Technical Challenges and Responses

Aerospace wiring harnesses need to adapt to extreme environments. The low temperature at high altitudes, the high temperature upon re-entry into the atmosphere, the near-vacuum pressure and cosmic radiation all pose severe challenges. The wiring harness is made of high-temperature resistant insulating materials such as polyimide and fluoroplastics to ensure stable operation in an environment above 200℃. Low-temperature resistant rubber and fluoropolymers ensure that the wiring harness maintains flexibility in extremely cold environments. Anti-radiation materials and metal braided layers effectively prevent damage from high-energy particles.

The balance between lightweight and high strength is of vital importance. The wiring harness uses aluminum alloy wires instead of copper wires, reducing the weight by approximately two-thirds. Aramid fibers and carbon fibers and other composite materials can reduce weight while enhancing mechanical strength. In terms of structural design, by optimizing the wiring scheme and adopting high-density connectors, the length and volume of the wire harness are reduced, and the mechanical stability is enhanced through the design of reinforcing ribs.

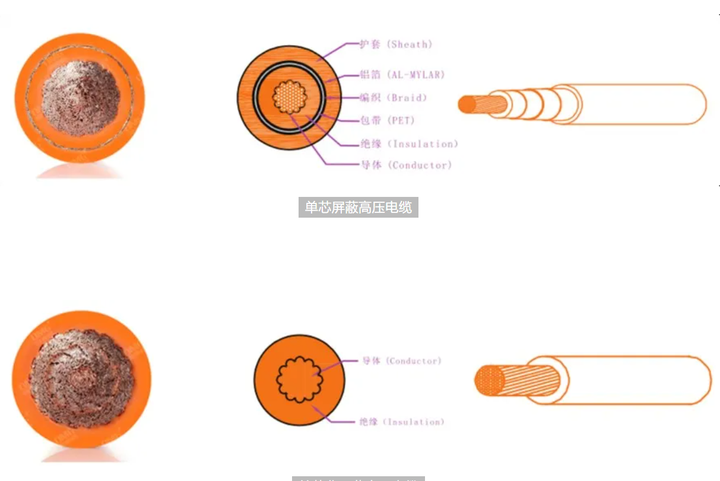

Outstanding anti-interference ability is the guarantee of security. The wire harness uses metal braided mesh and metal foil to shield electromagnetic interference. The twisted-pair and coaxial cable structure reduces signal distortion. Filtering technology and grounding design further ensure the purity of the signal. Reasonable wiring to avoid proximity to strong interference sources ensures the accuracy of data transmission.

III. Common Types: Wiring harness options to Meet Diverse Needs

Special wiring harnesses made of high-performance materials are suitable for extreme environments. Tin-plated copper core perfluoroethylene-propylene copolymer insulated wires and cables are resistant to high temperatures and corrosion, and are widely used in areas near engines. The aerospace radiation-resistant low-temperature flexible conductor is insulated with composite film and woven with synthetic fibers, maintaining flexibility and electrical performance even in a radiation environment at -196℃.

In terms of structural form, circular wiring harnesses are suitable for scenarios with compact space and the need for anti-interference, such as avionics equipment cabins. Flat wire harnesses meet the high spatial layout requirements of satellites and other equipment, are easy to install and maintain, and can reduce signal interference.

IV. Market Insights: Industry Status and Future

The global aerospace wiring harness market continues to grow. The sales of aerospace wiring harnesses reached 365 million US dollars in 2024 and are expected to increase to 465 million US dollars by 2031, with a compound annual growth rate of 3.5%. The growth momentum comes from the recovery of the aviation transportation industry, the increase in commercial aircraft orders and the frequent space exploration activities. New aircraft models such as the Boeing 787 have a high demand for wiring harnesses. The construction of small satellite constellations such as SpaceX's Starlink program has further promoted market expansion.

North America and Europe are traditional consumer markets, while the Asia-Pacific region has huge growth potential. The mass production of China's C919 passenger aircraft and the advancement of its space missions have driven the rapid development of the domestic wiring harness market.

The market competition is fierce. International enterprises such as TE Connectivity and Safran dominate with their technological strength and customer resources. Domestic enterprises such as AVIC Optoelectronics and Aerospace Electrical Appliances have gradually expanded their market share through technological innovation.

In the future, wire harness technology will develop towards high performance, lightweight, integration and intelligence. New materials such as ceramic matrix composites and carbon nanotubes will enhance the performance of wire harnesses. Integrated and modular design simplifies installation and maintenance. Automation and 3D printing technologies enhance production efficiency and quality consistency.

As the "neural network" of aerospace equipment, although the wiring harness is hidden behind the scenes, it is the cornerstone of flight safety and mission success. With the advancement of technology and the deepening of industrial cooperation, aerospace wiring harnesses will continue to illuminate the path for humanity's exploration of the universe.

If you have the need to buy bulk fuel aerospace wiring harnesses, you can try to contact us Aichie Tech Electronics Co., LTD., we have undertaken the production of various types of aerospace wiring harnesses, the price is favorable and the delivery time is short;

AICHIE Tech Electronics Co.,Ltd

Email: sales03@aichie.com

Mobile/Whatsapp/WeChat: (86)18027502150