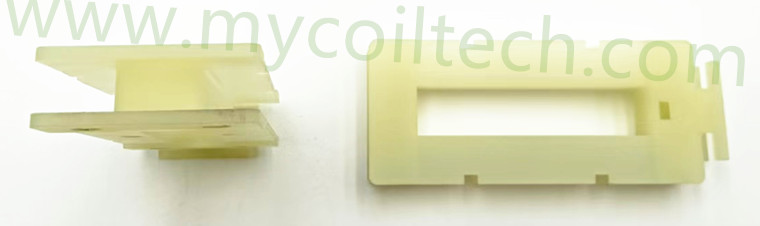

In the composition of a transformer, the bobbin (framework) is rarely mentioned as frequently as the coil or magnetic core, yet it is a key component ensuring the stable operation of transformers. It not only undertakes the important responsibility of fixing the coil but also serves as a core barrier for isolating high and low voltages and resisting high-temperature erosion. The selection of bobbin materials directly affects the safety, stability, and service life of transformers. Today, we focus on our company's exclusive material solutions for products — from selection standards to quality control details, we will comprehensively explain how our company builds product competitiveness with high-quality materials.

I. Our Star Products: Precise Material-Scenario Matching Cases

The bobbin material for each transformer model of our company is the closed-loop outcome of "scenario demand → material R&D → testing and verification → mass application". The following three star products’ material solutions can intuitively demonstrate our company's customized advantages:

1. EE16 High-Frequency Transformer: Exclusive PHENOLIC Bobbin, a Stable Choice for Industrial High-Frequency Scenarios

The EE16 high-frequency transformer focuses on industrial control power supplies and small inverters. It needs to operate continuously under high frequency (20kHz-100kHz) and high voltage (1kV-3kV). Our company exclusively equips it with a customized phenolic resin bobbin:

Material Adaptability: For high-frequency working conditions, the dielectric loss of the phenolic resin is strictly controlled below 0.008, avoiding temperature rise caused by dielectric loss heating under high frequency (the measured hot-spot temperature of the transformer is reduced by 5-8℃); the breakdown voltage of 18kV/mm can cope with occasional voltage fluctuations in industrial scenarios and eliminate the risk of electric leakage.

Practical Application Value: The EE16 transformer equipped with this exclusive phenolic bobbin can operate stably for 6 consecutive years in industrial control cabinets (the industry average is 4 years), with a failure rate as low as 0.3%. It has become a designated supporting product for over 30 industrial equipment manufacturers.

2. GU25 Pot-Type Transformer bobbin: Exclusive PA66 Bobbin, a Durable Option for Automotive Scenarios

The GU25 pot-type transformer focuses on on-board power supplies and smart home controllers. It needs to withstand continuous vibration (5-500Hz) during vehicle operation and installation impacts. Our company equips it with an exclusive nylon 66 (PA66) bobbin reinforced with 25% glass fiber:

Material Adaptability: The 25% glass fiber formula enables the bobbin to have an impact strength of 8kJ/m². After the on-board vibration test (50Hz/2g acceleration for 100 hours), the structure remains undistorted and the pins do not loosen; the heat distortion temperature of 260℃ can cope with the instantaneous high temperature of 120℃ in the on-board environment and prevent the bobbin from softening.

Practical Application Value: This GU25 transformer has passed the IATF16949 automotive electronics certification and is compatible with on-board OBC (On-Board Charger) of over 10 automobile manufacturers. In the -40℃~85℃ high-low temperature cycle test, the insulation performance retention rate is 100%, meeting the strict requirements of automotive electronics.

3. EFD20 Flyback Transformer bobbin: Exclusive PM-9630 Bobbin, an Efficiency Expert for Thin-Scenarios

The EFD20 flyback transformer focuses on laptop chargers and LED driver power supplies. It needs to achieve a thin design (thickness <12mm) while bearing a power density of 10W-60W. Our company equips it with a customized modified PM-9630 bobbin:

Material Adaptability: The modified PM-9630 has a flexural strength of 85MPa even in a 0.8mm thin-walled state, without cracking during winding; its optimized fluidity enables precise molding of the thin slot structure of the EFD20, controlling the overall thickness of the transformer at 11.5mm (the industry average for similar products is 13mm). Meanwhile, its long-term temperature resistance of 150℃ can cope with the hot-spot temperature of 140℃ of the flyback transformer.

Practical Application Value: The EFD20 transformer equipped with this bobbin is compatible with laptop chargers of over 5 consumer electronics brands. When operating at full power of 60W, its temperature rise is 6℃ lower than that of similar industry products, and it meets the UL 94 V-0 flame retardant standard, achieving both thinness and safety.

II. Our Material Advantages: Controlling from the Source to Create Value for Customers

Our company's core competitiveness in bobbin materials lies not merely in selecting high-quality materials, but in establishing a complete system of "material R&D - source traceability - full-process quality control":

Exclusive R&D Capability: We have established a material R&D laboratory and customize material formulas for different product scenarios (such as low-dielectric-loss phenolic resin for EE16 and modified PM-9630 for EFD20), breaking the industry pain point of "general materials being used for all scenarios".

Source Traceability Management: We establish traceability files for each batch of materials, recording supplier qualifications, material batch numbers, and performance parameters to ensure materials are traceable and accountable.

Full-Process Quality Control: From raw material warehousing (sampling and performance testing) → production process (real-time monitoring of molding parameters) → finished product delivery (100% appearance inspection + 10% performance sampling inspection), each link is controlled in accordance with standards higher than the industry average to ensure the stable material quality of the final products.

Choosing a transformer essentially means choosing "material reliability". Our company has always adhered to the belief that "high-quality materials create high-quality products". Through exclusive customized bobbin material solutions, we provide customers in different scenarios with transformer products that are "more stable, more durable, and more adaptable".

Before cooperation, we can provide customers with test samples. Of course, we also offer product customization services. Feel free to contact us if you have any needs.

Contact us today to explore bulk orders or request technical specifications.

Email: sales008@mycoiltech.com

Whats app ID: +86 18788862885

Name:Alex~Mycoiltech

IESMAT SEM Workshop in January 2025

IESMAT SEM Workshop in January 2025 IESMAT SEM Seminar in Feb, 2025

IESMAT SEM Seminar in Feb, 2025 IESMAT Most Recent SEM Seminar in Sep, 2025

IESMAT Most Recent SEM Seminar in Sep, 2025