How Rogers RT/duroid 6010.2LM Achieves Ultra-Low Loss and Stable 10.2 Dk for Compact X-Band PCBs

How Rogers RT/duroid 6010.2LM Achieves Ultra-Low Loss and Stable 10.2 Dk for Compact X-Band PCBs

Introduction

In the rapidly advancing world of high-frequency electronics, achieving optimal performance demands specialized materials engineered for precision and reliability. Rogers Corporation's RT/duroid 6010.2LM laminates stand at the forefront of this technology, offering an exceptional ceramic-Polytetrafluoroethylene (PTFE) composite solution. Specifically formulated for circuits operating at microwave frequencies where stringent electrical characteristics are non-negotiable, this laminate leverages its high dielectric constant (Dk) to enable significant circuit miniaturization. By facilitating more compact and highly efficient designs, the 6010.2LM empowers engineers to push the boundaries of size and performance. Its exceptionally low loss properties make it the substrate of choice for critical applications operating within the X-band spectrum and lower frequency ranges, where signal integrity is paramount.

Advanced Features

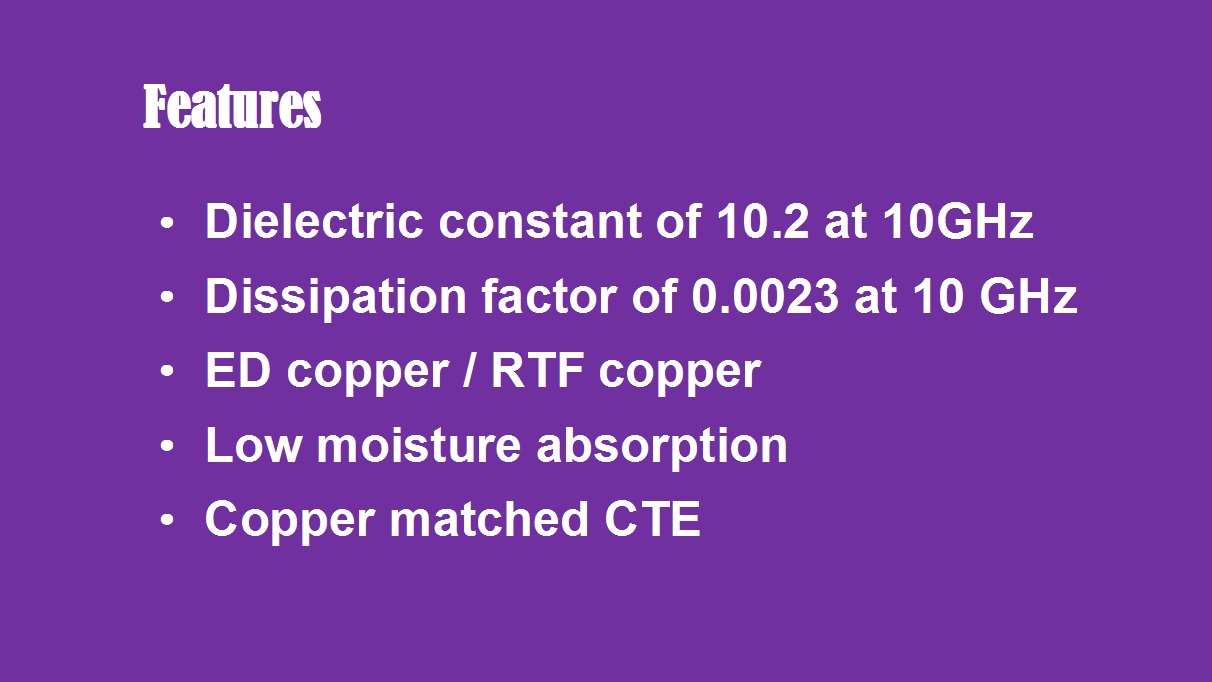

The Rogers 6010.2LM laminate distinguishes itself through a suite of meticulously controlled properties designed to deliver consistent, high-performance results:

2.1 Exceptional Dielectric Constant (Dk) Control:

Boasting a high Dk value of 10.2 coupled with an impressively tight tolerance of±0.25, the 6010.2LM provides unparalleled stability in electrical performance. This precise Dk control is fundamental for predictable impedance management and resonant frequency accuracy, ensuring consistent, repeatable circuit behavior essential for high-yield manufacturing and reliable end-use operation.

2.2 Ultra-Low Dissipation Factor (Df):

Signal loss is a critical enemy in high-frequency applications. The 6010.2LM substrate combats this effectively with an exceptionally low dissipation factor of just 0.0023 measured at 10 GHz. This ultra-low loss characteristic minimizes signal attenuation and distortion over distance and through components, facilitating highly reliable and efficient signal transmission crucial for sensitive communication and radar systems.

2.3 Flexible Copper Foil Options:

Recognizing the diverse needs of PCB fabrication and performance optimization, the Rogers 6010.2LM PCB offers a choice between Electro-Deposited (ED) copper and Reverse-Treated Foil (RTF) copper. This critical flexibility allows designers and manufacturers to tailor their selection based on specific requirements, whether prioritizing ultra-low insertion loss for signal integrity, minimizing Passive Intermodulation (PIM) for sensitive receivers, or optimizing surface roughness for bonding and etching processes.

2.4 Minimal Moisture Absorption:

Environmental resilience is key for long-term reliability. The 6010.2LM laminate exhibits very low moisture absorption characteristics. This inherent resistance to humidity helps preserve its stable electrical properties (like Dk and Df) over time and under varying environmental conditions, reducing performance drift and enhancing the operational lifespan of the PCB.

2.5 Optimized Coefficient of Thermal Expansion (CTE):

Thermal management is critical, especially in complex multi-layer structures. The CTE values for the RT/duroid 6010.2LM are carefully engineered at 24 ppm/°C in the X and Y axes, and 47 ppm/°C in the Z-axis. This specific CTE profile is crucial for enhancing the long-term reliability of plated through-holes (PTHs) in multi-layer boards. It helps minimize stress during thermal cycling, ensuring robust and secure electrical connections between layers, thereby contributing significantly to the overall structural and functional integrity of the assembly.

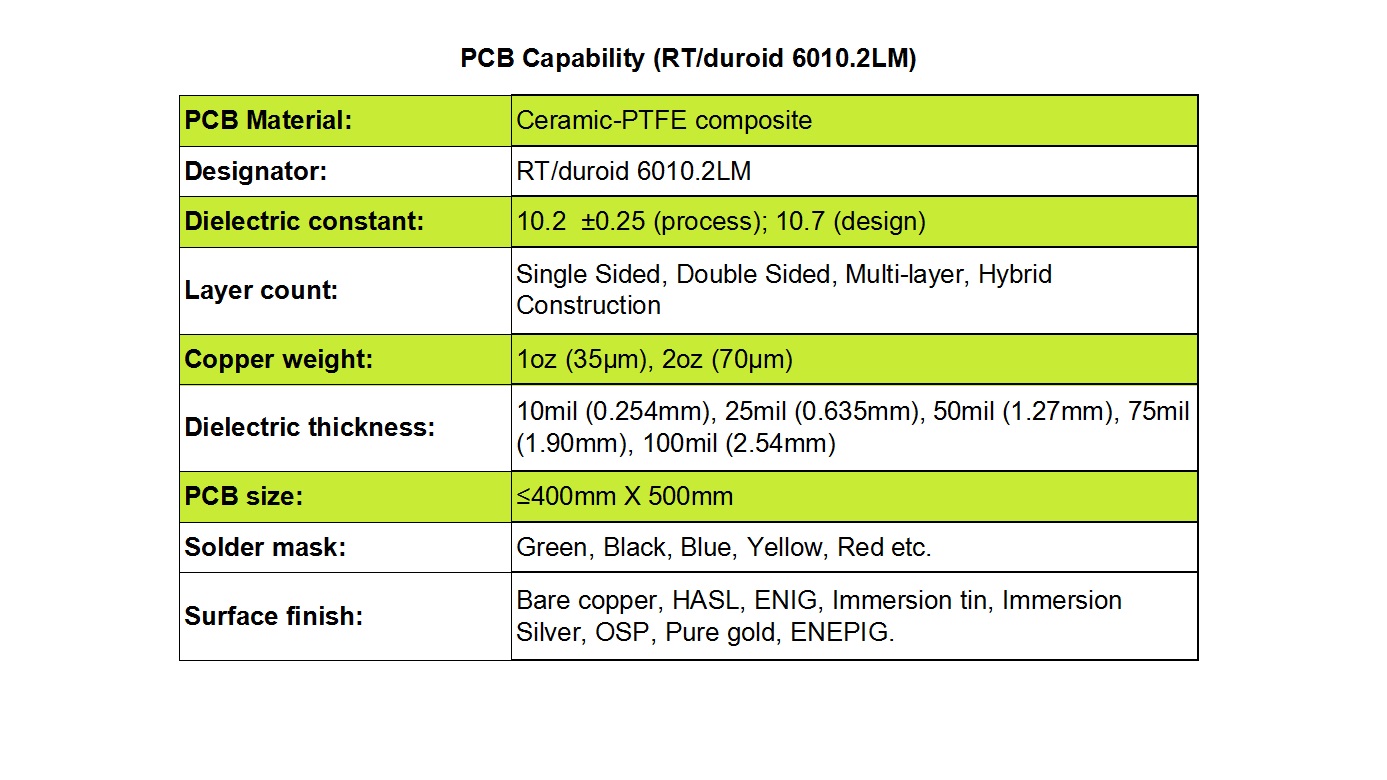

Demonstrated PCB Manufacturing Capabilities with 6010.2LM

Leveraging the advanced properties of Rogers RT/duroid 6010.2LM requires a manufacturing partner with proven expertise and versatile capabilities. We possess the specialized processes and stringent quality controls necessary to fully harness the potential of this demanding material:

3.1 Complex Configurations:

We expertly manufacture a wide array of board structures to meet diverse design challenges, including Single Sided, Double Sided, sophisticated Multi-layer builds, and Hybrid constructions combining 6010.2LM with other compatible materials (like FR-4 or other RF laminates) to optimize cost and performance.

3.2 Material Thickness & Copper Weight Flexibility:

We offer standard dielectric thicknesses of 10mil (0.254mm), 25mil (0.635mm), 50mil (1.27mm), 75mil (1.90mm), and 100mil (2.54mm). Copper weights of 1oz (35µm) and 2oz (70µm) are standard, with other weights potentially available upon request, providing design flexibility for current carrying capacity and impedance control.

3.3 Generous Panel Sizing & Solder Mask Options:

Our manufacturing process accommodates panel sizes up to 400mm x 500mm, optimizing material utilization for larger boards or efficient panelization. Aesthetic and functional requirements are met with a range of solder mask colors, including Green, Black, Blue, Yellow, Red, and more.

3.4 Comprehensive Surface Finishes:

To ensure optimal solderability, wire bondability, shelf life, and electrical performance, we provide a full spectrum of surface finish options. Choose from Bare Copper, HASL (Lead-Free), ENIG (Electroless Nickel Immersion Gold), Immersion Tin, Immersion Silver, OSP (Organic Solderability Preservative), Pure Gold (Hard/Soft), ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold), and others based on your specific application needs.

3.5 High-Frequency Expertise:

Our processes are specifically refined for handling low-Df, tight-tolerance RF PCB materials like 6010.2LM, focusing on precise etching, lamination control, and meticulous drilling to maintain impedance accuracy and signal integrity.

Critical Applications Enabled by RT/duroid 6010.2LM PCBs

The unique combination of high Dk, ultra-low loss, and excellent stability makes RT/duroid 6010.2LM PCBs indispensable in a variety of demanding high-frequency applications where performance, reliability, and size are critical factors:

Patch Antennas & Phased Arrays: Enables compact, efficient radiating elements with precise beam patterns, ideal for communication links and radar systems.

Satellite Communications (Satcom) Systems: Provides the stable, low-loss platform needed for uplink/downlink transceivers and onboard processing in harsh space environments.

High-Power Amplifiers (HPAs): Supports efficient power transfer and thermal management in amplifiers for radar and communication transmitters.

Avionics & Radar Systems: Critical for aircraft collision avoidance systems (ACAS/TCAS), ground radar warning systems, altimeters, and weather radar, where reliability and signal clarity are paramount for safety and mission success.

Military & Defense Electronics: Used in radar systems (ground-based, naval, airborne), secure communications, electronic warfare (EW), and guidance systems requiring robust performance.

Telecommunications Infrastructure: Found in high-frequency base station components, point-to-point microwave backhaul links, and emerging 5G/6G infrastructure where low loss and size efficiency are crucial.

How Rogers RT/duroid 6010.2LM Achieves Ultra-Low Loss and Stable 10.2 Dk for Compact X-Band PCBs

1. Material Composition: Engineered Ceramic-PTFE Composite

The foundation of RT/duroid 6010.2LM’s performance lies in its proprietary ceramic-PTFE (polytetrafluoroethylene) composite. This hybrid structure synergizes:

Ceramic fillers (e.g., alumina): Provide high dielectric constant (Dk=10.2) through dense polarizable molecules.

PTFE matrix: Delivers ultra-low loss by minimizing dipole relaxation losses at microwave frequencies.

The homogeneous dispersion of ceramics in PTFE suppresses energy dissipation mechanisms, achieving a dissipation factor of 0.0023 at 10 GHz–critical for X-band (8–12 GHz) efficiency.

2. Precision Dk Stability: Tolerance Control (±0.25)

Stability is ensured through:

- Controlled filler distribution: Uniform ceramic particle size eliminates localized Dk variations.

- Cross-linked PTFE: Enhances molecular rigidity, reducing thermal drift.

Moisture resistance: <0.1% water absorption prevents Dk fluctuations in humid environments.

This allows impedance tolerances≤1%–vital for phased-array antennas and filters where phase consistency impacts beamforming.

3. Loss Mitigation Mechanisms

Ultra-low signal attenuation results from:

- Minimal conductor roughness: RTF copper options reduce skin effect losses at X-band frequencies.

- PTFE’s non-polar nature: Lacks ionic impurities that cause dielectric relaxation.

- Low hysteresis: Ceramic-PTFE bonds dissipate minimal heat under RF cycling.

This preserves signal integrity in high-power amplifiers and radar systems.

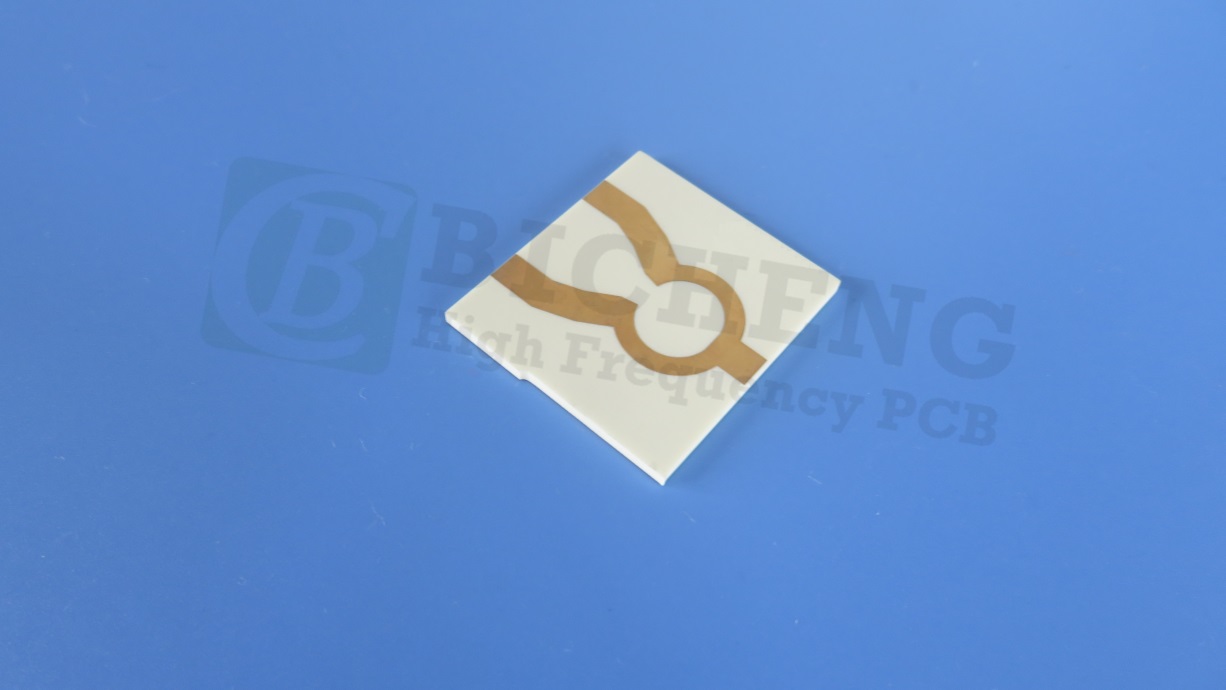

4. Miniaturization Advantages

The high Dk (10.2 vs. FR-4’s ~4.5) enables wavelength reduction by >50% via:

- Shorter trace lengths: Resonant structures (e.g., patch antennas) shrink proportionally to 1/√Dk.

- Reduced layer counts: High Dk allows multi-layer consolidation without crosstalk.

Example: A 10 GHz microstrip antenna on 6010.2LM occupies ~60% less area than on low-Dk substrates.

5. X-Band Optimization

Performance at X-band leverages:

- Flat dispersion curve: Dk varies <2% from 5–15 GHz, avoiding phase distortion.

- CTE matching: In-plane CTE (24 ppm/°C) aligns with copper, preventing delamination during thermal cycling in avionics.

- Z-axis stability: 47 ppm/°C CTE ensures plated through-hole reliability in multi-layer boards.

Conclusion

RT/duroid 6010.2LM high frequency PCB achieves its benchmark performance through material physics innovation: Ceramic fillers enable high Dk/size reduction, while PTFE delivers loss control. Tight process tolerances (±0.25 Dk), moisture resistance, and CTE engineering then translate these properties into reliable X-band operation. For designers, this means compact, high-Q circuits with uncompromised signal fidelity in radar, satcom, and 5G infrastructure.

Rogers RT/duroid 6010.2LM high-frequency laminates represent a superior material solution for engineers pushing the limits of microwave circuit design. Its tightly controlled dielectric properties, ultra-low loss, environmental stability, and thermal reliability make it ideal for the most demanding applications in aerospace, defense, telecommunications, and advanced sensing. As your specialized PCB manufacturing partner, we combine deep expertise in processing this advanced material with comprehensive capabilities–from complex multilayer and hybrid constructions to diverse finishing options–to deliver high-performance PCBs tailored to your exact specifications. Partner with us to leverage the full potential of RT/duroid 6010.2LM and achieve unparalleled success in your next high-frequency project.