Why is RF-35 a Top-Tier, Cost-Effective Material for Commercial Microwave and RF Designs?

In the rapidly advancing world of wireless technology, the selection of the right printed circuit board material is paramount to the success of any high-frequency application. For engineers and designers seeking an optimal blend of performance, reliability, and cost-efficiency, Taconic's RF-35 High Frequency PCB laminate emerges as a premier solution. This blog post delves into the superior properties, extensive manufacturing capabilities, and diverse applications of RF-35, underscoring why it is a standout material for your next project.

An Introduction to RF-35 High Frequency PCB Laminate

Taconic RF-35 is a high-performance, organic-ceramic laminate belonging to Taconic's esteemed ORCER series. This material is engineered with a woven glass reinforcement system, synergizing the company's profound expertise in advanced ceramic filler technology with a specialized coated PTFE (Polytetrafluoroethylene) fiberglass substrate. A key differentiator of RF-35 is its utilization of 7628-style fiberglass, which provides an exceptional balance of mechanical stability and electrical performance, offering outstanding value. It is notably available in consistent thickness increments of 10 mils (0.254 mm), facilitating straightforward design and integration.

This Taconic RF-35 substrate is specifically engineered to serve as an ideal substrate for cost-sensitive, high-volume commercial microwave and radio frequency (RF) products. It boasts excellent peel strength, significantly surpassing standard epoxy-based materials. This is critical for both half-ounce and 1-ounce copper weights, ensuring robust connections that can withstand rework and repair processes without failure. Furthermore, RF-35 exhibits an ultra-low moisture absorption rate and a remarkably low dissipation factor (Df). These characteristics are vital for maintaining stable electrical performance, as they effectively minimize undesirable phase shift and signal loss across a broad frequency spectrum.

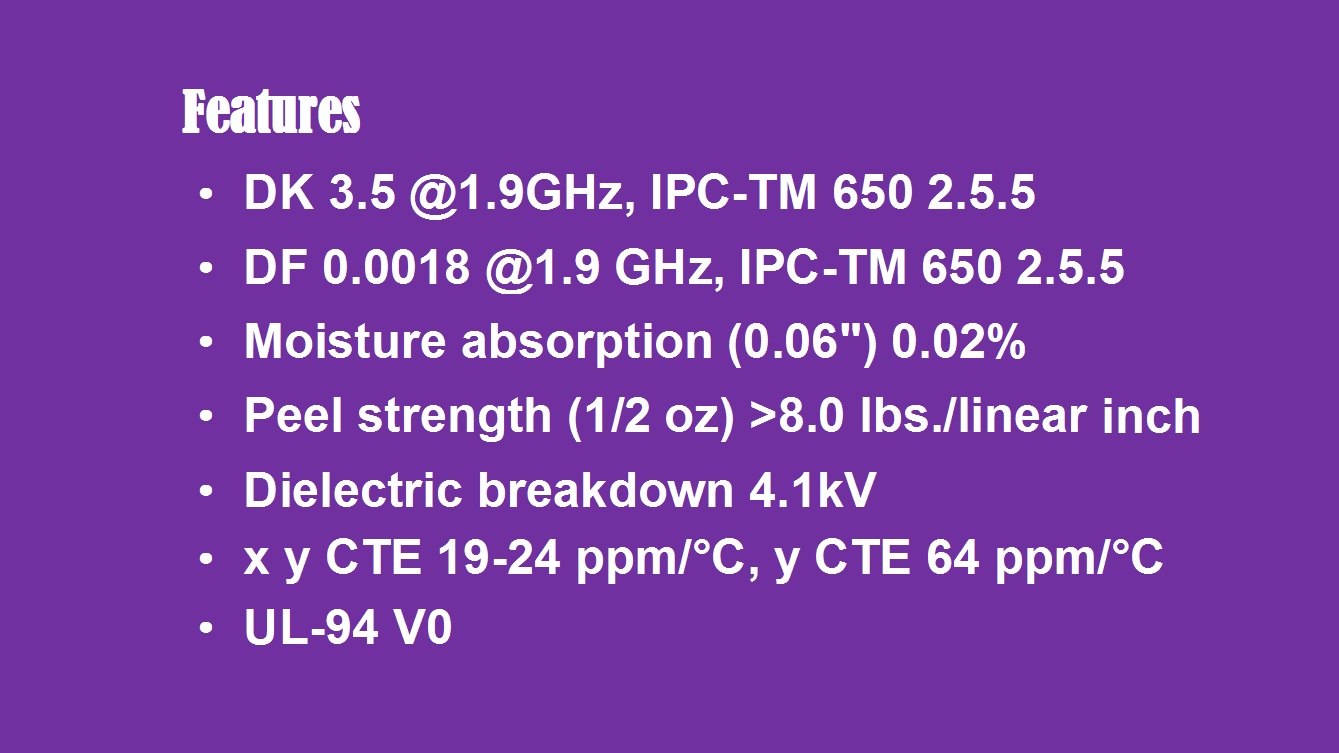

Detailed Analysis of Key Parameters

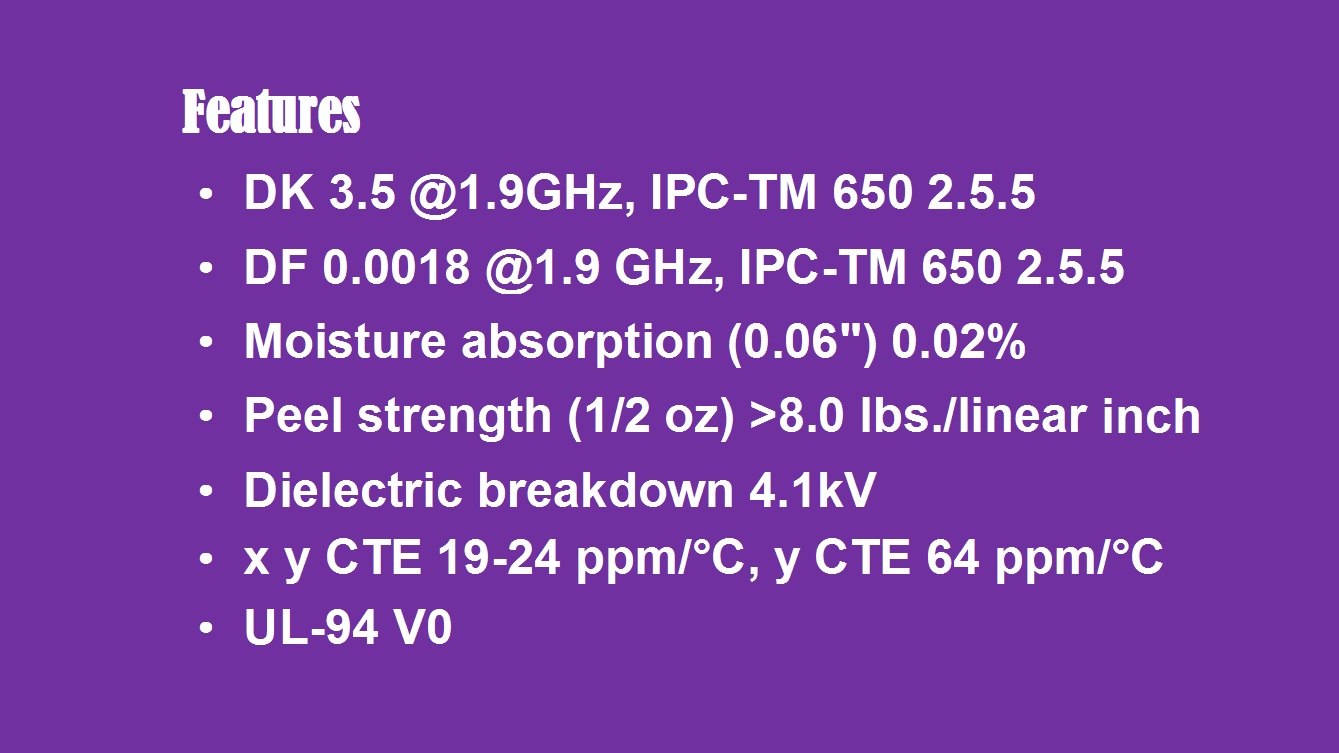

The exceptional performance of RF-35 is quantitatively validated through rigorous testing per IPC and ASTM standards, providing designers with reliable data for their simulations and calculations.

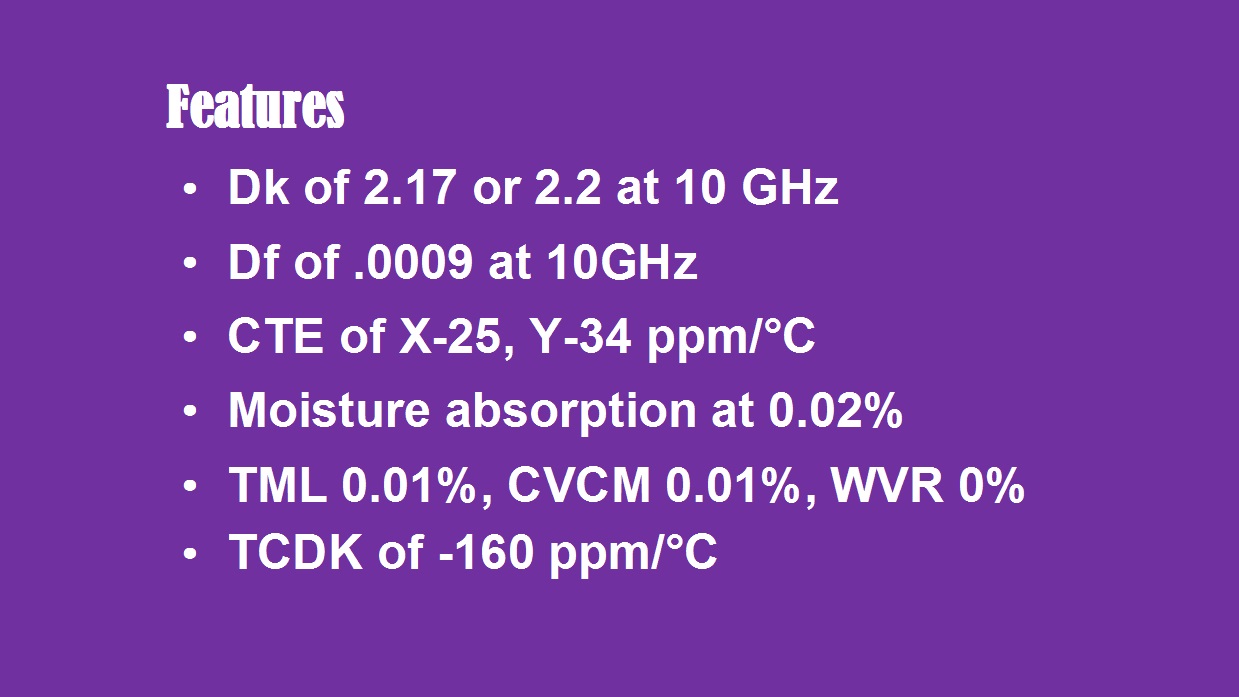

1)Dielectric Properties: At a test frequency of 1.9 GHz (IPC-TM 650 2.5.5), RF-35 demonstrates a stable dielectric constant (Dk) of 3.50 and an extremely low dissipation factor of 0.0018. This combination of low Dk and minimal signal loss is precisely what makes it ideal for high-frequency circuits where preserving signal integrity is absolutely crucial.

2)Moisture Resistance: As per IPC-TM 650 2.6.2.1 testing on a 0.060-inch thick sample, the material's moisture absorption is a mere 0.02%. This extremely low value ensures that the board's electrical properties remain consistent even in varying environmental conditions, preventing performance degradation due to humidity.

3)Mechanical Strength: The peel strength, a direct measure of the bond between the copper and the laminate, is exceptional. For½oz. copper, it exceeds 8.0 lbs/linear inch, and for 1 oz. copper, it surpasses 10.0 lbs/linear inch (IPC-TM 650 2.4.8). This high strength prevents delamination and ensures reliability.

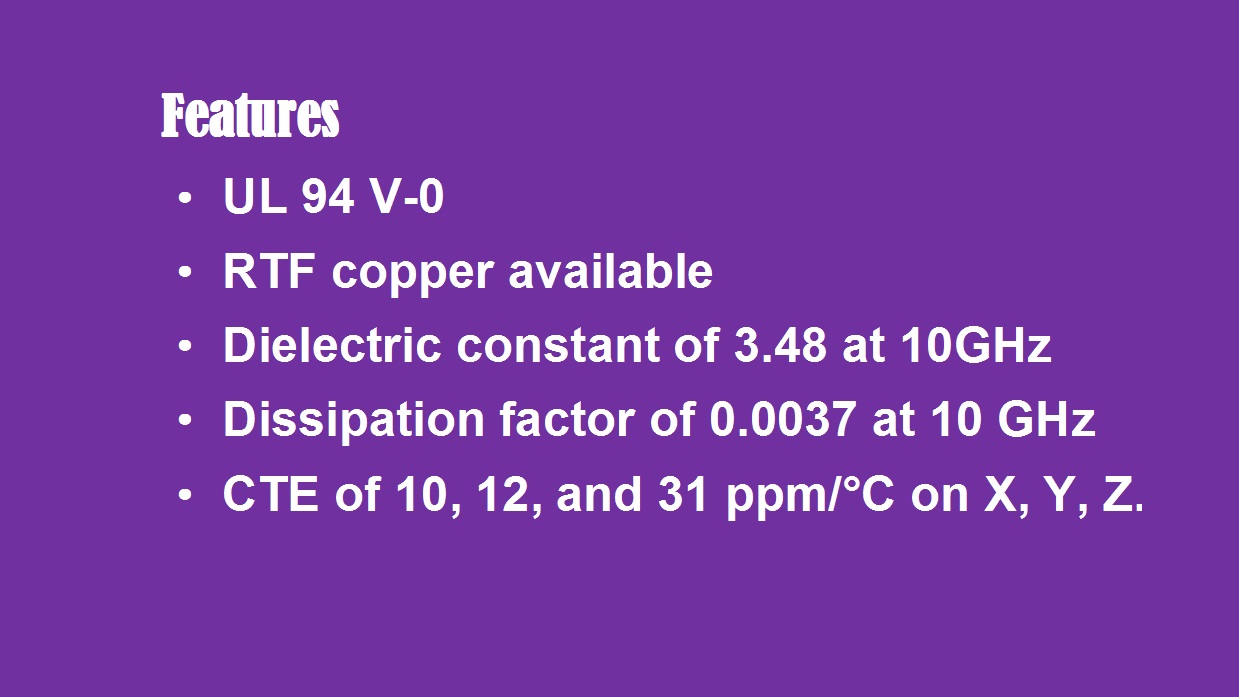

4)Electrical and Thermal Reliability: The dielectric breakdown strength, tested per IPC-TM 650 2.5.6, is rated at 41 kV, indicating high voltage resistance. Its coefficient of thermal expansion (CTE) is measured by ASTM D 3386 (TMA), with x/y CTE values of 19 and 24 ppm/°C and a z-axis CTE of 64 ppm/°C, providing good dimensional stability during thermal cycling. Finally, it carries a flammability rating of UL-94 V-0, meeting critical safety standards.

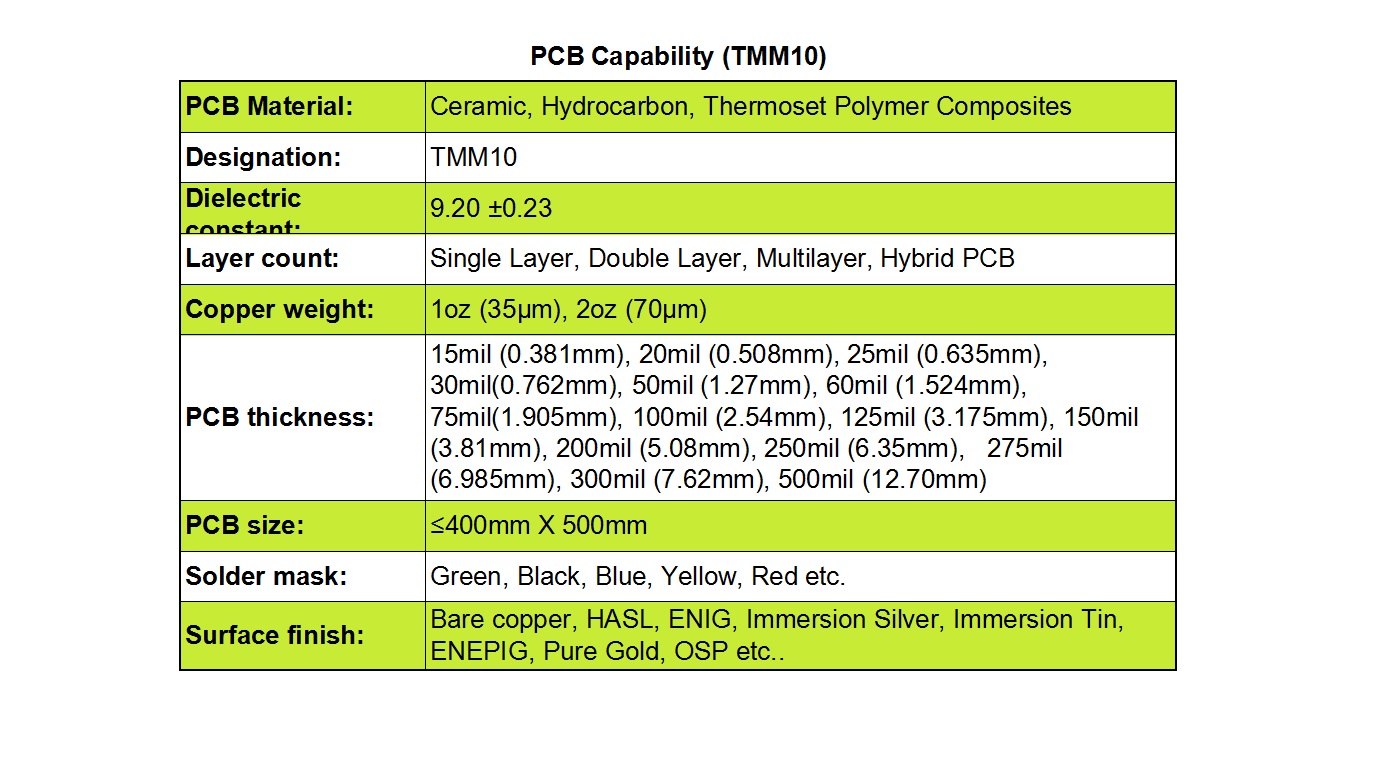

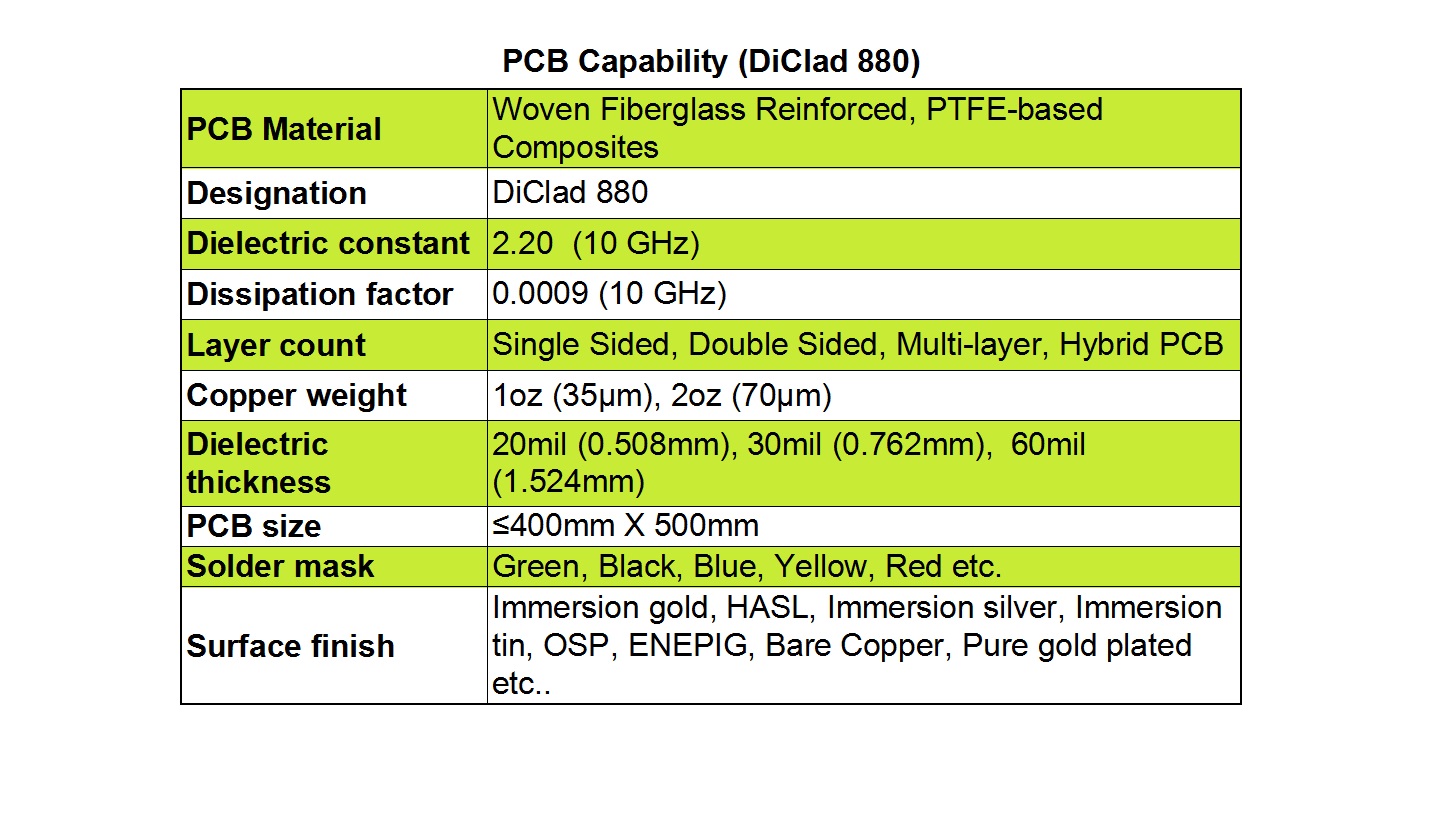

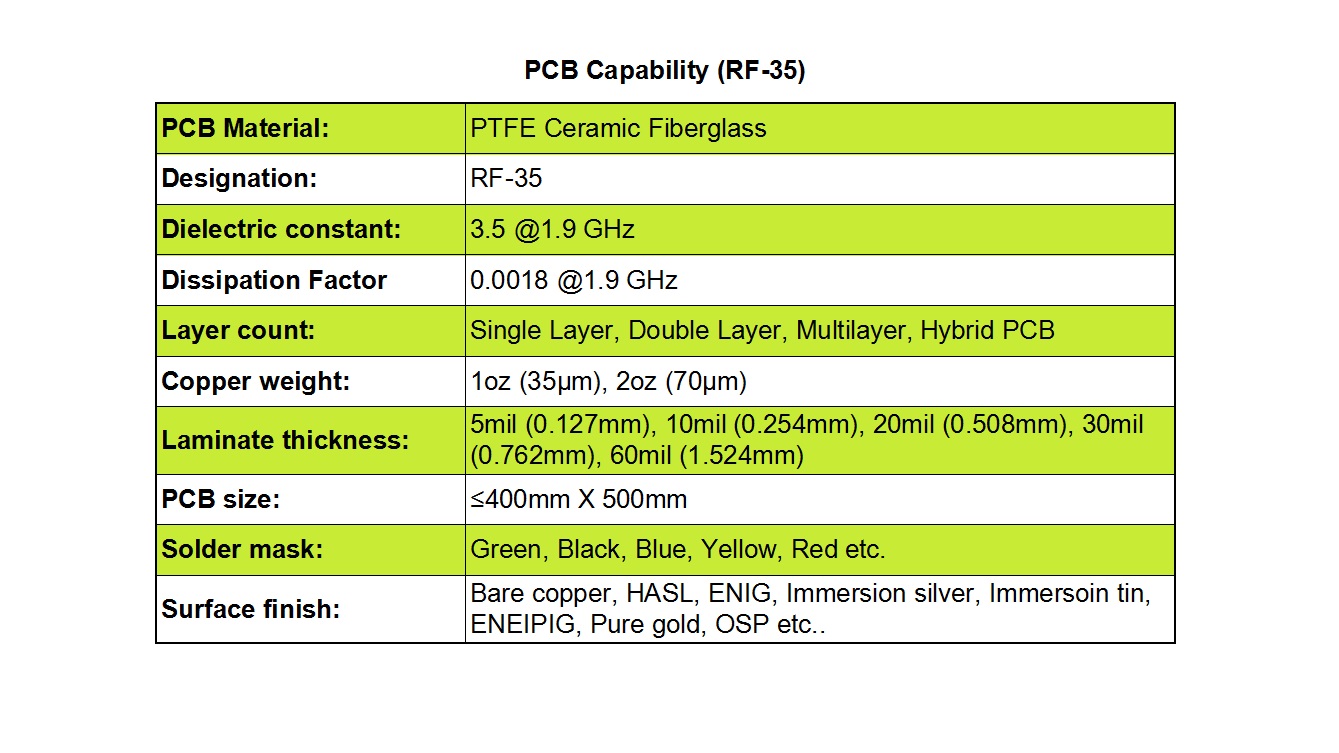

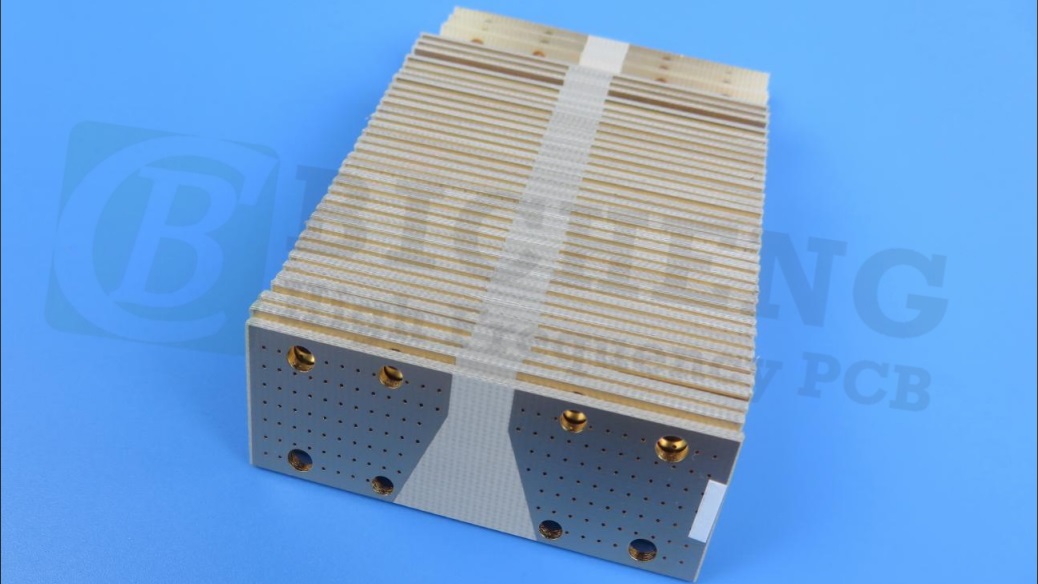

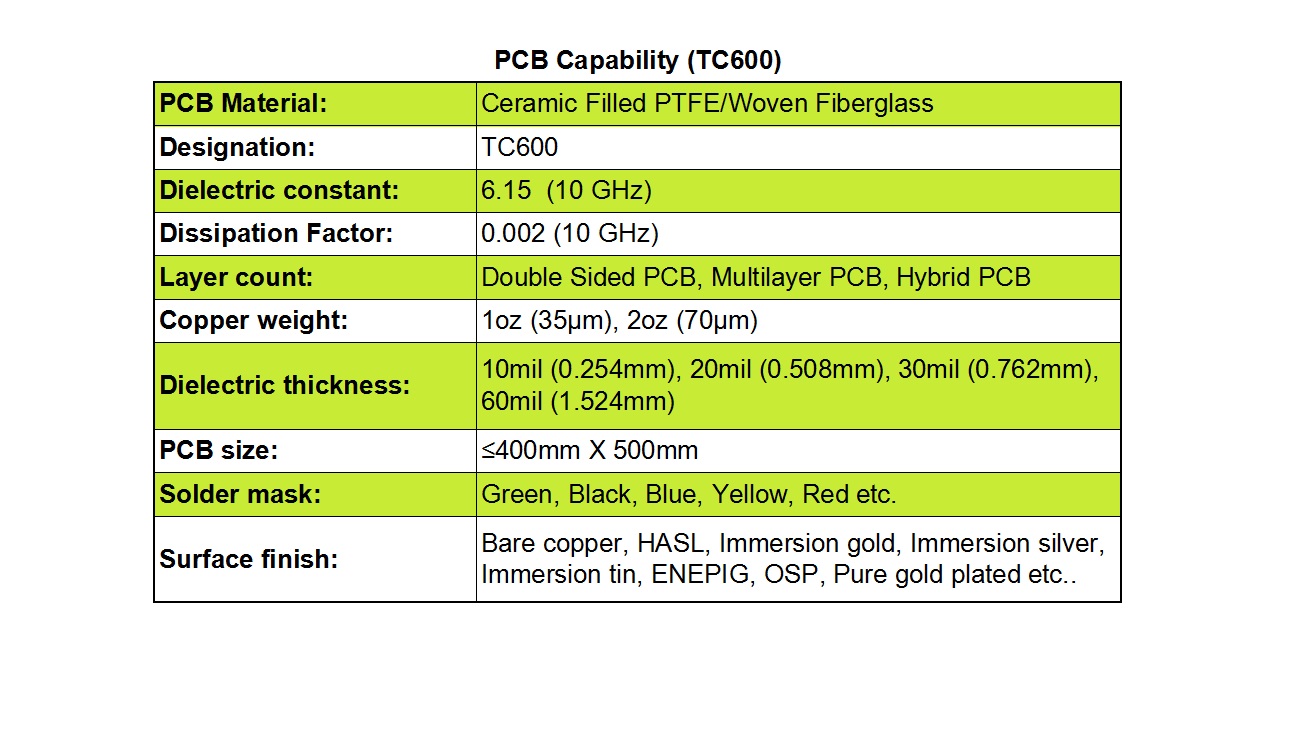

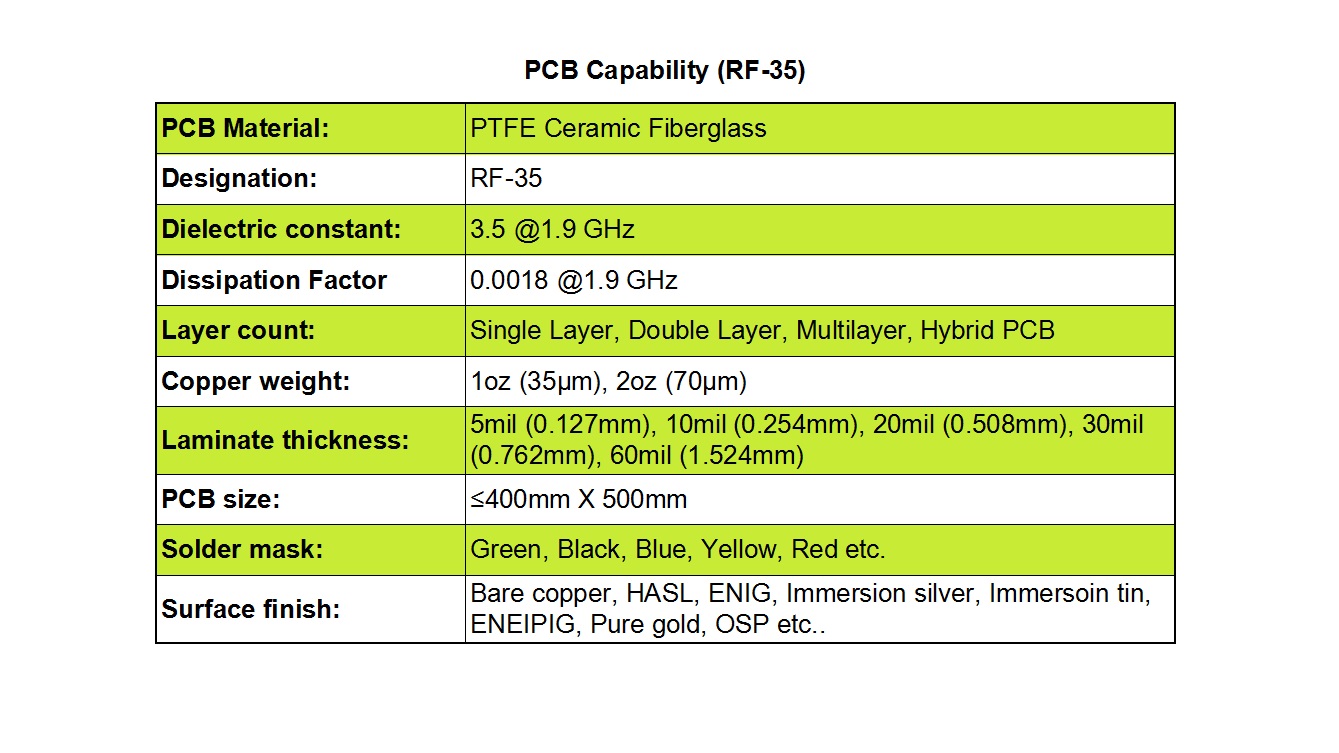

PCB Manufacturing Capabilities with RF-35

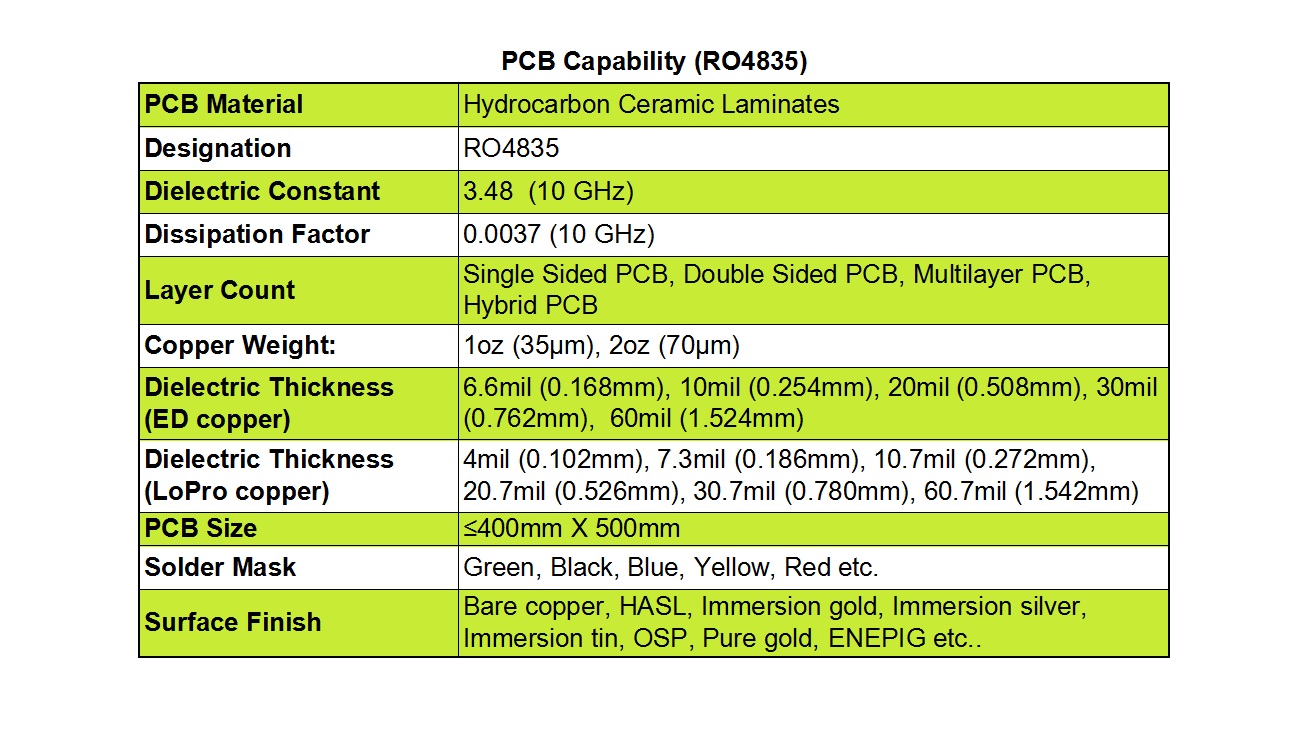

We offer comprehensive and versatile fabrication services tailored to fully leverage the advantages of RF-35 PCB laminate, accommodating a wide array of project specifications.

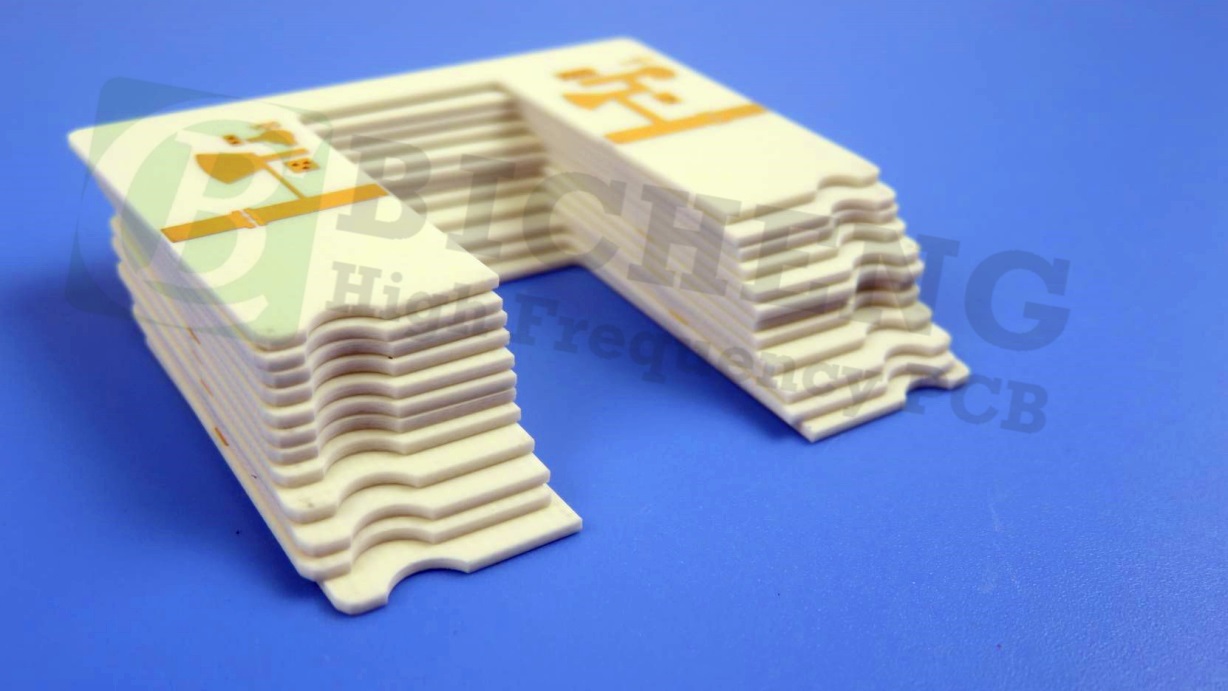

1)Board Construction: We can manufacture single-layer, double-layer, complex multilayer, and hybrid multilayer PCBs, providing design flexibility for various application complexities.

2)Copper and Laminate Thickness: Standard copper weights include 1oz (35µm) and 2oz (70µm). We provide a selection of laminate thicknesses including 5 mil (0.127 mm), 10 mil (0.254 mm), 20 mil (0.508 mm), 30 mil (0.762 mm), and 60 mil (1.524 mm).

3)Panel Size: We support PCB sizes up to 400 mm x 500 mm, offered either as individual boards or as multi-size arrays within a single panel, maximizing production efficiency.

4)Aesthetics and Finish: A variety of solder mask colors are available, including green, black, blue, yellow, and red. We also provide a comprehensive range of surface finishes such as Bare Copper, HASL, ENIG, Immersion Silver, Immersion Tin, ENEPIG, Pure Gold, and OSP to meet specific assembly and performance needs.

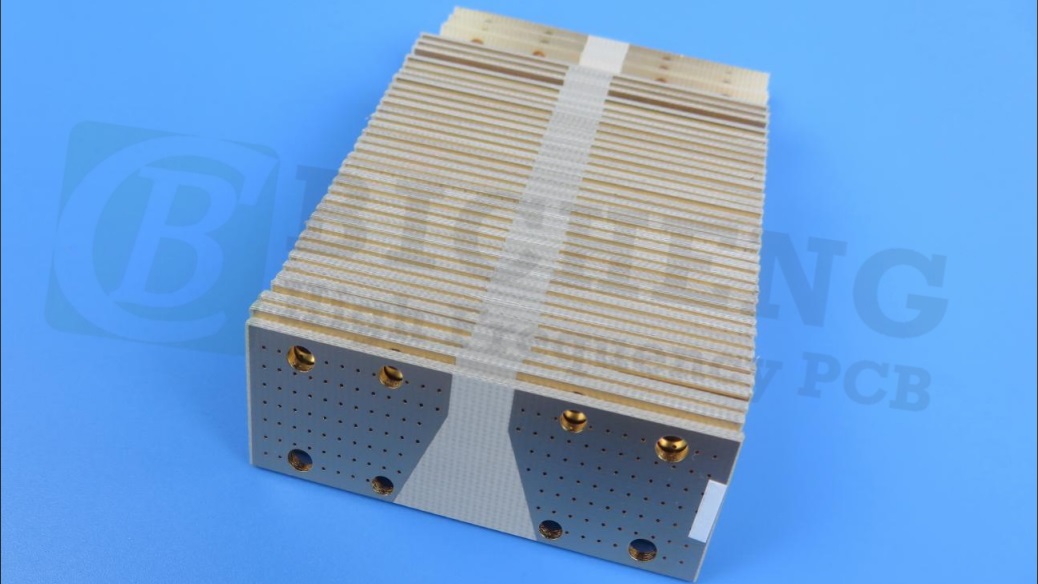

Primary Applications

The superior electrical and mechanical properties of RF-35 high frequency PCB make it exceptionally well-suited for a multitude of critical RF components. It demonstrates strong performance in power amplifiers, filters, couplers, and a wide array of other passive components essential for modern communication systems, satellite technology, and radar applications.

Conclusion

For OEMs and designers navigating the challenges of high-frequency electronics, RF-35 PCB represents a proven, high-value material solution. Its certified electrical parameters, outstanding reliability, and our extensive manufacturing support make it a top contender for your most demanding commercial RF and microwave projects. Contact us today to discuss how we can partner to bring your innovative designs to life with RF-35 High Frequency PCBs.