Breaking Boundaries CIQTEK Launches the Next-Generation Q-Band EPR Spectrometers

The 15th China Symposium on Electron Paramagnetic Resonance (EPR) Spectroscopy was successfully held at Chongqing University from October 24 to 27, 2025. Nearly one hundred experts, scholars, industry representatives, and graduate students gathered to discuss cutting-edge topics in the EPR field, including new techniques and theories, biological spin labeling, and new energy applications.

Grand Launch: CIQTEK Q-Band EPR Spectrometers Make a Stunning Debut

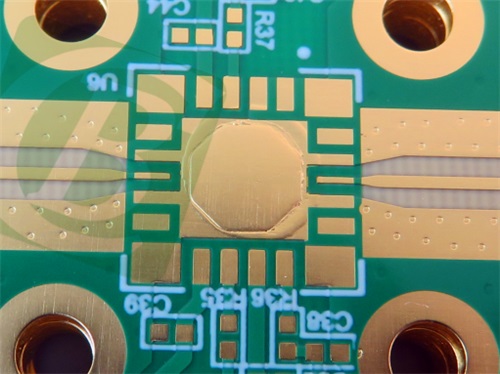

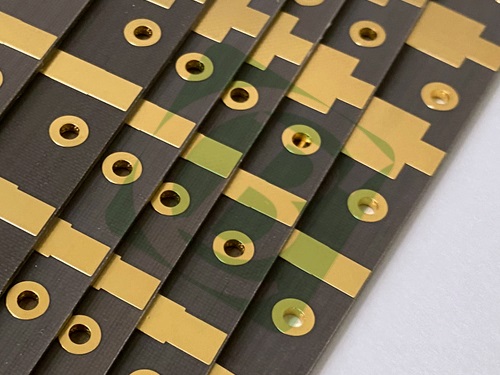

As a pioneer in paramagnetic resonance technology, CIQTEK officially unveiled its new Q-band EPR spectrometer series — the EPR-Q400 High-Frequency Pulse Spectrometer and the EPR-Q300 Continuous-Wave Spectrometer, marking another significant milestone in high-frequency EPR technology.

Compared with traditional X-band EPR, high-frequency EPR offers:

-

Higher spectral resolution

-

Stronger orientation selectivity

-

Enhanced sensitivity

Making it a powerful tool for biomacromolecular structure studies, spin dynamics research, and materials science applications.

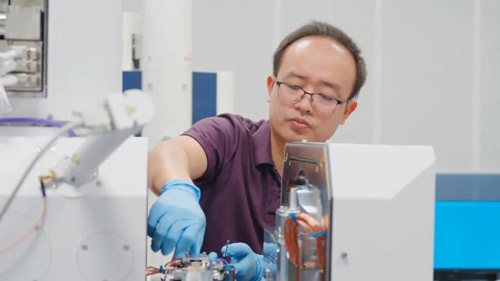

Dr. Richard Shi from CIQTEK Introduces the New Q-Band EPR Instruments at the Meeting

Dr. Richard Shi from CIQTEK Introduces the New Q-Band EPR Instruments at the Meeting

Flagship Model: EPR-Q400 High-Frequency Pulse Spectrometer

The EPR-Q400, the flagship model of this release, supports both CW and pulsed EPR measurements, meeting a wide range of research demands. It enables variable-temperature experiments from 4 K to 300 K, providing flexible and precise experimental conditions.

Notably, the Q-band spectrometer adopts the same software platform as CIQTEK X-band EPR systems, greatly reducing the learning curve and ensuring a seamless and user-friendly operation experience.

Dedicated CW Solution: EPR-Q300 Continuous-Wave Spectrometer

For users focusing solely on continuous-wave EPR experiments, CIQTEK introduced the EPR-Q300, offering a targeted and efficient solution for diverse scientific applications.

Continuous Innovation in EPR Technology

This product launch showcases CIQTEK’s robust R&D capabilities and in-depth technical expertise in EPR spectroscopy, thereby further enriching its EPR product portfolio. During the symposium, multiple experts recognized CIQTEK’s responsive and professional technical support, noting that the team not only helps resolve experimental challenges but also actively participates in collaborative research, contributing to high-level scientific achievements.

Upcoming Event: CIQTEK Paramagnetic Academy 2026

To further promote academic exchange and talent development in EPR technology, the CIQTEK Paramagnetic Academy Advanced EPR Workshop will be held from July 17 to 27, 2026, in conjunction with the CIQTEK EPR User Symposium.

These events will serve as an open platform for technical communication, experience sharing, and application discussions among EPR researchers and users.

Stay tuned for more updates and upcoming event announcements.